Power distribution in electrical panels and junction boxes is a very apparent need for different applications. Joints/junctions must be done securely and safely for ensuring that they are efficient and safe for the operator. Losses on such junction can be fatal for the equipment and to personnel deployed on the facility.

Conventionally such connections were made by drilling – tapping current bars. Occasionally such junctions are made using copper alloy strips with screws. Integrator of panels, over the years, have realized that both these methods are electrically inefficient and involve substantial cost & labor in doing it. These methods implement the conductor clamping mechanisms which are not validated by any international standards. Sometimes such junction becomes the weakest link when final equipment undergoes type test. And weak junctions may attract substantial liabilities at that point in time. One method does open power junctions which are not safe where-as the other does clamping of a conductor using screws that directly pierces them.

Elmex Electric Pvt. Ltd. is a company established in 1963 in the western province of India. Elmex is actively involved in innovating terminal blocks for different applications and with different conductor clamping methods.

Elmex has a range of very innovative products referred to as ‘Distribution Blocks’. These products have been in the application domain for more than 15 years and have proved their worth.

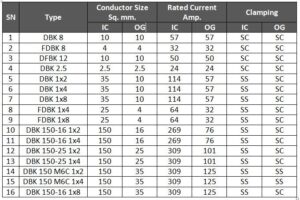

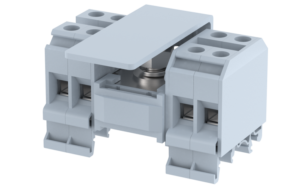

The core philosophy of the Distribution Block is to evenly distribute incoming current to the outgoing nodes. Distribution Blocks have incoming at the center that offers bolted joints (secure stud termination) and the option to user to select between screw clamping(SC) or secure stud clamping(SS) for outgoing nodes. Users may select a suitable part number based on the application.

Conventional distribution arrangements were frugally made so mounting of current bars was done using supports that offer limited flexibility to the user. The electrical clearance of such an arrangement is also limited and also non-standard. This in most cases compromises the safety levels.

‘elmex’ Distribution Blocks are DIN Rail mounted and hence provide flexibility in mounting. These blocks are designed, developed and type tested as per IEC 60947-1. This means that ‘elmex’ Distribution Blocks are qualified products with reference to international standards. This qualification is awarded after following tests are conducted on these blocks:

· Temperature rise test at rated current

· Dielectric tests

· Verification of clearances and creepage distance

· Verification of thermal characteristics

· Pull out test

· Mechanical strength and attachment of the block on DIN Rails.

The above mentioned are a few important tests as per international standard(IEC 60947-1). The tests are mentioned here for reference and the actual sequence of tests while type tests may differ.

Salient features of ‘elmex’ Distribution Blocks:

1. Compact, Low loss, and DIN-Rail mountable.

2. Finger safe with protection shroud at the center and IP20 outgoing nodes.

3. The construction ensures even distribution of currents.

4. Off-the-shelf version for different applications.

5. Outgoing nodes can accept flexible/solid conductor with Pin type lugs and the incoming node can accept ring/fork type lugs.

The following table may be used for selecting an appropriate distribution block for an application:

‘elmex’ Distribution Blocks can be used in a different type of applications be it pole top junction boxes for power distribution in local facilities – a normal practice in Asian countries, underground transformer distribution stations or LV distribution kiosk – a normal practice in African countries and within power panels for uniform load distribution and centralized control. The smaller version of distribution blocks like DBK 2.5 and FDBK 8 are becoming choice for BMS and HVAC integrators in gulf countries.